Upper Intake Manifold OptionsThis was originally a "DIY" upper intake porting page, but I decided to expand it to cover all the possibilities:

Buildyour own intake:Warning: Math! (Thanks to Alex for pointing out my mistake!) L = ((ECD × 0.25 × V × 2) ÷ (rpm × RV)) - ½D To compute the intake runner length (L), we need to know a few things: -Effective Cam Duration (ECD) = 720° (4 cycle engine) - Advertised Cam Duration (Factory ~248° ) - 20° (lifter slop) -Runner Diameter (D) = 1.5 (or so) -Speed of Sound (V) = 1250 to 1300 fps,depending on temperature (use 1300) -Reflective Value (RV) = How many times is the air going to bounce before the intake valve opens? Use 2 for LONG runners with high RPM's or 4 for short runners with moderate RPM's. -Revolutions Per Minute (rpm) = 2500 for a good street intake, low RPM, daily driver or tow. ECD = 720° - (248° - 20°) The ECD of the factory cam would be: 492 The formula for "optimum" intake runner length (L), with are numbers would be: L = ((492° × 0.25 × 1300 × 2)÷(2500 × 4)) - 0.75 ...or L = ((319800)÷(10000)) - 0.75 ...or 31.98 - 0.75. Meaning L = 31.23" from the Plenum to the valve face. Now, the lower intake is 5" long and the head is 3" to the valve face. So, L = 31.23 - (5" + 3") or L = 23.23" (Stump-pulling Torque Intakes) Upper runner length = 23.23" for 1.5" intake tubes tuned at 2,500 RPM, 4th bounce. Upper runner length = 55.21" for 1.5" intake tubes tuned at 2,500 RPM, 2nd bounce. Upper runner length = 17.9" for 1.5" intake tubes tuned at 3,000 RPM, 4th bounce. Upper runner length = 44.55" for 1.5" intake tubes tuned at 3,000 RPM, 2nd bounce. (Screaming Banshee Autobahn Intakes) Upper runner length = 9.02" for 1.5" intake tubes tuned at 4,500 RPM, 4th bounce. Upper runner length = 26.78" for 1.5" intake tubes tuned at 4,500 RPM, 2nd bounce. Upper runner length = 7.24" for 1.5" intake tubes tuned at 5,000 RPM, 4th bounce. Upper runner length = 23.23" for 1.5" intake tubes tuned at 5,000 RPM, 2nd bounce. Notice something strange about the first and last line? Just a coincidence? No, a harmonic! This is why long tubes are better, you have two peaks one at 2,500 RPM's (4th bounce RAM) and one at 5,000 (2nd Bounce RAM). Using 1.5" aluminum tube, and the flanges cut off an existing manifold (too easy!), weld up an intake similar in looks to the Mustang GT-40. The plenum should be 3" tube and displace 90in3 (or 1/2 you engines displacement), the runners are determined with the formula (above) based on your desired RPM. Buy a new/used one:For those that are not "financially challenged", call your local wrecking yard and get the complete composite upper from a '02 and later Ranger or '01 and later Taurus/Sable. Make sure to get everything, intake, TB, air inlet hoses, clamps, throttle cable, etc. as these will make it a truely bolt-in mod. RPS Memeber testing reveals that the composite intake is good for a few HP over a stock '98 Ram, but the '98 Ram intake can be modified more. The same thing can be done using the '98-'01 "Ram" intake (equal length runners, large plenum). The BBK 1548 Throttle Body is 56mm (vs stock 50mm). While ment for the 94-01 Ford Mustang 3.8L V-6, it bolts to the '98-'01 intake perfectly. To make it a "drop-in", you will have to swap throttle shafts. Not too tough... Thanks to RangerBill for heading that one up, now only if we can get BBK to produce them! Now something everyone (except the composite intake users) can benifit from: Modify your existing:First visit the Standard Abrasives Web Site and check out the DIY Guides. They have an excellent site that offers all the parts and directions you need to do ths mod. Remove Upper Intake (The tools and steps below assume the Upper Manifold is already off the engine.) Tools and equipment for Porting/Port Matching the upper intake:

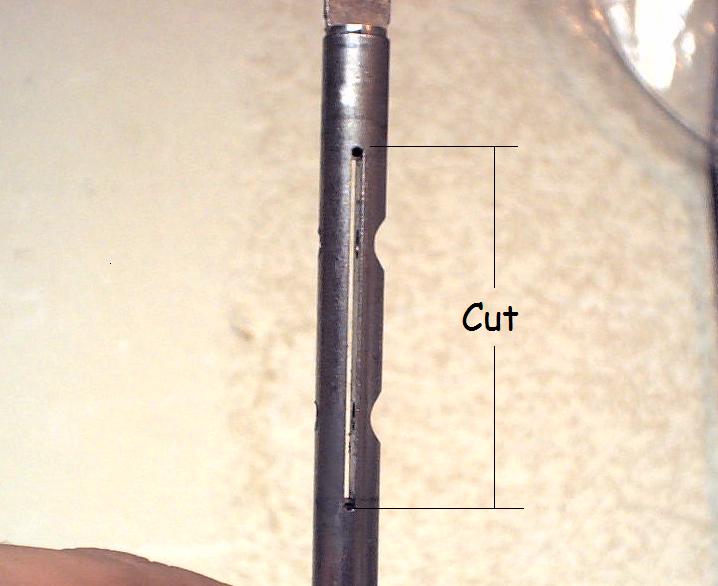

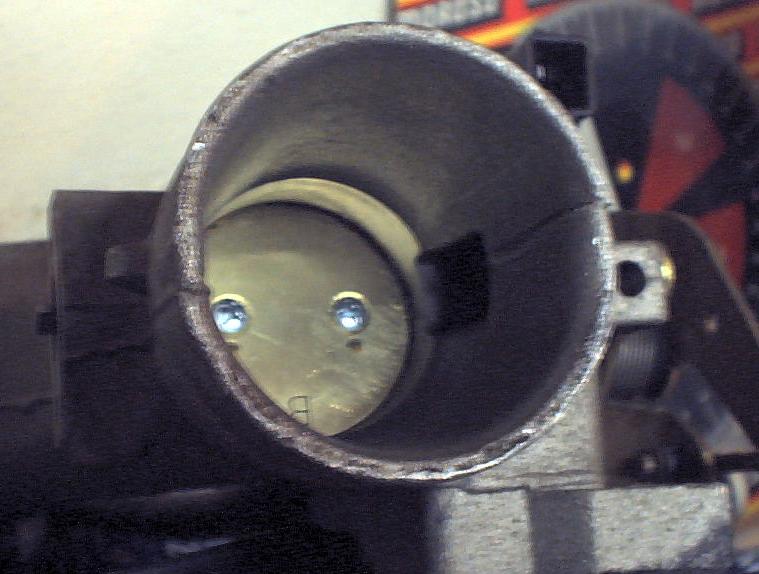

-Place the manifold on a work bench or other well lit, clear area. -Manifold should be secured with the mounting flange facing up (upside down). -Lay an Upper Intake Manifold Gasket over the flange and use at least 2 mounting bolts (or small clamps), at the far ends, to properly align the gasket. -Mark the areas to be removed with a scribe, machinists dye or spray paint. -Spray bit of choice with liquid penetrant. -With light even pressure, slowly grind material to the edge of marked lines. -Intake runners should be rough but uniformly flat (no gouges) -Frequently spray the bit with liquid penetrant (w/ each port, at least) to keep aluminum from clogging it. -when finished, repeatedly run fresh water through each end of the manifold until all traces of shavings are gone. -Reinstall vacuum tee with teflon tape (or pipe dope) on threads. -Return to Phenolic Spacer Installation directions for reinstalling the Upper Intake. For the Adventurous...Find someone who has experience at welding cast aluminum. Using a fine toothed metal cutting blade and a bandsaw, cut the upper manifold (on the vertical axis) just above the 90 degree bend. This is to allow access to the short side radius for porting. Cut again in a "J" (on the vertical axis) starting the hook about 2" behind the throttle shaft on '97 and earlier or the Throttle Body Mounting Flange on '98 and up. This is to gain access to the plenum. Using the materials listed above (plus a basic or deluxe porting kit from Standard Abrasives, less than $50), port the upper intake runners to ~1.5". It would be best to have a ball of this diameter to pass through each port to check for uniformity. The dividers in the plenum should be ground to a smooth tapered blade to cleanly cut the air without turbulance. All internal surfaces and edges should be clean, smooth and free from gouges. Have the pieces welded back together. They should be done in short segments 180 degrees apart to limit warpage. Once cool, concenrate on the outside of the manifold to remove welding build-up, slag and casting flash. Go to 3M's site or Caswell's Plating site (follow the links for buffing aluminum) to learn how to smooth and polish you upper intake!! Talk about a custom manifold! What about the throttle body?(All) Well, that one is easy! First, grind the throttle stop (see below) to ensure the throttle plate is at 90° to the intake floor when at Wide Open Throttle (W.O.T.).  With the throttle wide open, carefully grind the threaded ends off the throttle plate screws (since they are "staked" to keep them in place), and remove the butterfly plate. Look CAREFULLY at the throttleshaft, as you are going to cut the drilled side off, leaving just the threaded half of the shaft (a process know as "half-shafting").  Once you are absolutely positive which side is to be removed, use a coping saw or cutoff wheel to remove that half of the throttle shaft. Carefully grind the remaining nubs flush. This simple mod will increase the air through your stock TB at least 5%.  For even more airflow, thin the front (stamped) side of the throttle plate as much as possible, and taper it to the ends (from the shaft, straight out). Do not get too close to the edge or you will have idle speed problems! Countersink the bolt holes (again, not all the way through!) and use M4-.7x8mm oval head machine screws to secure it.  To reassemble, center the shaft and tighten ONE screw. Treat the other screw with 3m® Loctite® 271 "Red" for a permanent mount. After it has set (5 minutes or more), remove the remaining screw and Loctite® it as well. After they have completely cured (24 hours), grind any exposed threads flush with the throttleshaft. Cheap and easy!  Want more? How about these photos to give you an idea of how far you can take the stock intake?

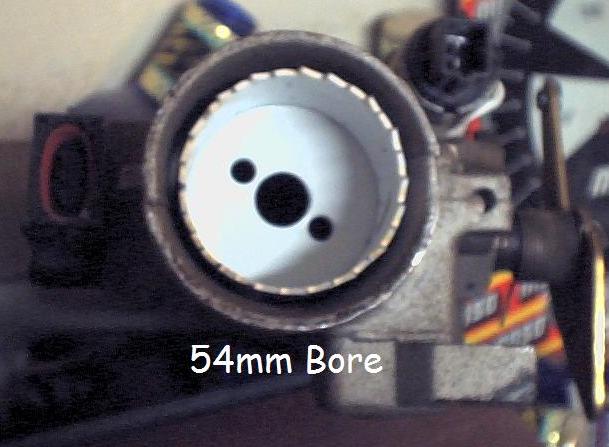

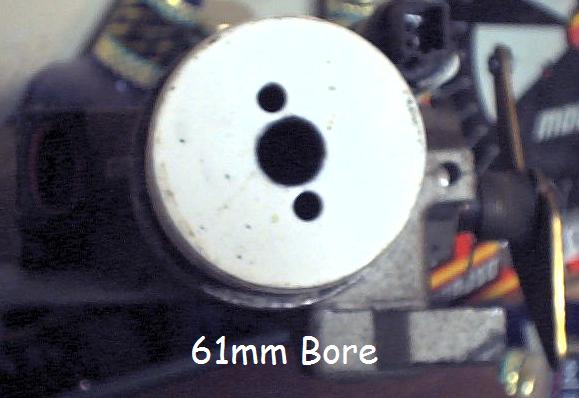

('97 Taurus): These are plentiful, and since I have two laying around, I decided to give them the once over. The 4.6L Mustang TB is a direct bolt up, will post picks soon! ('98-'01): BBK TB P/N 1548 for the 3.8L Mustang will work on with minor throttleshaft mods or swap your factory throttleshaft to make it a perfect swap! ('02 Composite): [posted by "rangeredge02 on RPS] "You can use a 60mm throttlebody off of an '01 or '02 escape 3.0 (Duratec) on the composite style intake. The bolt pattern is the same but you have to modify the intake mounting flange a little so it will not leak. Just be careful when port matching your intake to the new tb. You might want to buy a spare composite intake through Ford. It is only 60 bucks. A throttle body from a 3.8 winstar will bolt up but the linkage is on the opposite side of your tb." Hmmmm.... |

Go to Rogue

Performance!